nanodeck®

refinement consists of nanoparticles as well as 2 further components.

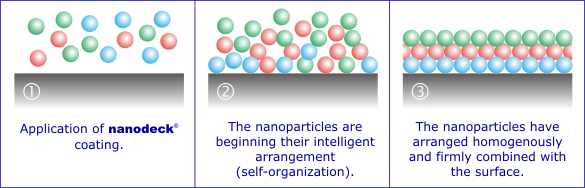

During application the nanoparticles arrange and organize themselves "intelligently".

The binding component (red) moves towards the refined surface and forms

a homogenous compound with it - that is, in a way, it becomes part of

the surface. This "self-organization"

results in an ultra slim, glass-hard layer (yellow) that guarantees an

extreme durability and protects the surface from aggressive

environmental influences. The non-stick component (blue) aligns up

towards the air and this way causes the so-called "lotus effect" as well as the "easy-to-clean-effect".

When

set, the nanodeck® refinement

is extremely chemically and mechanically resistant. It is heat-resistant up to a temperature of 450 degrees Celsius (850 degrees Fahrenheit), UV- and frost resistant. As a side effect the surface consistency and scratch resistance

are significantly improved, so that a mechanical wear and tear caused

by normal usage is almost completely prevented. Even aggressive

environmental influences have no effect any more. Refined surfaces can

be cleaned with a high-pressure water blaster (max. 100 bar). Depending on the sub-surface, brushes can also be used.

When set the refinement is absolutely innocuous, skin-neutral and food harmless. When used properly and set nano refinements thus do not have any hazardous health effects.

Nanotechnology

products have been tried and tested for years and are subject to

continuous improvement, which leads to an optimal adjustment to

surfaces and their material characteristics like glass, ceramics,

stone, concrete, plaster, brickwork, natural stone, textiles… for

further information, see nanodeck®

products.

|